Customised production thanks to in-house tool making

At Haver & Boecker, every new product development starts with the computer-aided implementation of your wishes and common ideas. In many cases, a simple realisation matures in the process: We will not get far with mere standard solutions. A wide range of our wire cloth solutions are individually designed for your application and are therefore custom-made. The solution: We develop and build new tools and devices ourselves – as well as special machines, interlinked production lines and optimal packaging.

We continuously refine our weaving looms

And we can therefore quickly adapt to technological progress

The control over our production processes starts with the fact that we design and manufacture our looms ourselves. It continues in controlled production conditions up to clean room atmospheres. The know-how from our weaving loom construction and our GeoDict simulation software also enable the solution-oriented development of new types of wire cloth.

A high level of tool making

Own machines for turning, milling or eroding

Our special machine and tool design department supplies CAM data for our CNC-controlled machine tools in addition to the drawings. Here are also created:

- Classic punching and deep-drawing tools

- Fully automated machines and handling systems

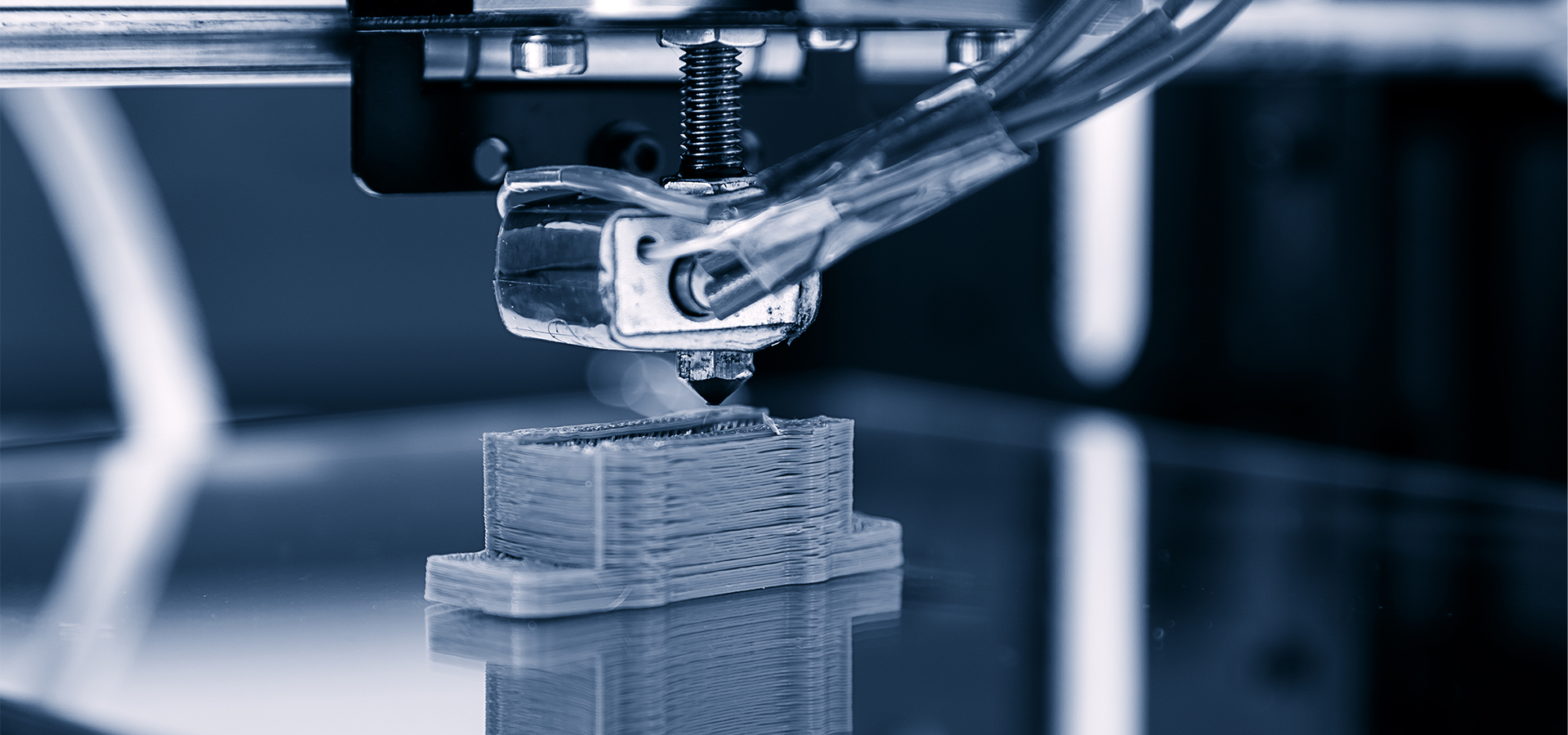

- Plastic injection moulds for filter production

Design of wire cloth products

Internal and external specifications are incorporated here

To enable you to optimally integrate our wire cloth solutions, our engineers, technicians and product designers implement your ideas and wishes on a modern 3D CAD system and create technical system and detailed drawings. Based on this data and the results of our feasibility check, the products are woven and assembled in our production.