Microfilters in the household and industry

Less microplastics in sewage treatment plants

Everyday life without plastic? Unimaginable nowadays. Too diverse are the areas of application of synthetic materials, which we understand by the commonly used term "plastic".[1] Plastics are used in a wide range of domestic and industrial applications.

From packaging, textiles, toys, cosmetics, and everywhere in between – plastics have become interwoven into our day-to-day lives. They are used in the production of insulation materials, cable sheathing, car tires and synthetic resins.

The list is virtually endless.

Unfortunately, the devastating effects that microplastic emissions have on nature and our environment are as well-known as the fact that marine life contaminated with particles return to humans in the form of food. In fact, we consume up to five grams of microplastics per week through the food we eat.[2]

The complete elimination of plastics in companies and private households, although desirable, is virtually impossible to achieve in the short term. It is therefore particularly worthwhile to take a look at how microplastics enter our sewage systems and, to some extent, the environment, as sewage treatment plants are not able to retain all components.

The sooner entry can be prevented, the sooner microplastic emissions that affect the environment and the effort required in the treatment process can be reduced.

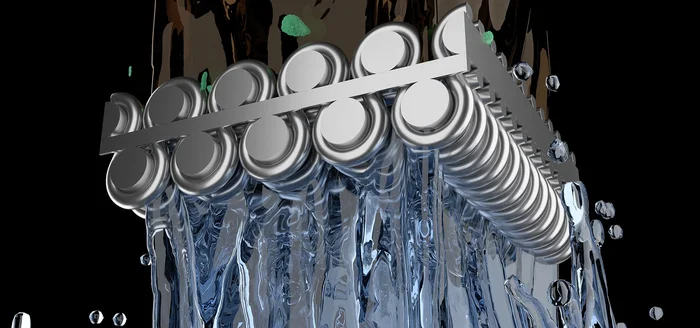

It is at this point that filter elements for domestic and industrial cleaning processes become particularly interesting. They can retain microplastics and other fine particles in plants and machinery, reducing water pollution and the consumption of key resources.

1. Figures and key routes of entry of microplastics into the environment

2. Efficient barriers for microplastics

2.1 Household and industrial wastewater

2.2 Road drains

3. Optimal design of a microfilter

3.1 Metal wire mesh filter medium

3.2 Success factors of „metal mesh filters in household appliances and industrial plants”

Info box - plastic & microplastics

Plastics are understood as being solid materials that are partially comprised of synthetic polymers. These include thermoplastics, duroplastics, and elastomers, as well as products such as paints, textile fibres and tyre abrasion the particles, fibres and fragments of which are classified into macroplastics (> 5mm), microplastics (5 mm – 1 μm), and nanoplastics (< 1 μm) according to their largest size.[3]

1. Figures and key routes of entry of microplastics into the environment

According to the Fraunhofer Institute, over 4 kg (8.8 lbs) of microplastics are released into the environment per capita and year in Germany. This amounts to a total of circa 330,000 t per year.[4]

A great proportion of microplastics flows into the environment with water.

First and foremost, it is natural precipitation and wastewater - a mixture of dirty water, rainwater run-off, and mixed water - that carries microplastic particles and introduces them into rivers, standing bodies of water, and the soil. However, not all microplastics are the same. Below we break this broad terminology into individual types based on the origins of microplastic emissions.[5][6]

2. Efficient barriers for microplastics

It is the responsibility of municipal wastewater treatment plants and competent engineering companies to find filtration solutions that are able to remove nearly all plastic particles from wastewater. Nevertheless, it is at least equally important to use barriers at an early stage to filter out the particles before they enter the wastewater in the first place.

Experts from a wide range of industrial sectors are therefore also responsible for finding efficient as well as economical solutions for water filtration.

2.1 Household and industrial wastewater

With a share of 66%, the greatest risk comes from primary type B microplastics.[8] These are released when products containing plastic are used or processed.

Applied to private households and industries as entry routes for microplastics, this includes the individual rinsing and washing process in which microplastics can enter wastewater. Filter elements are already being implemented during this process to retain a large proportion of the microparticles and discharge them separately.

But that’s not all.

The shape and design of the filters contribute toward conserving resources and reducing energy costs during the utilisation and service phase. The lower tendency of the filter to become clogged results in a decrease in the energy consumption and, at best, the water consumption as well.

At a time when hygiene is more important than ever before and the volume of laundry being done is increasing, energy prices are rising, directives to conserve resources are being put in place, and a shortage of water due to climate change is upon us. This is leading to a re-orientation of thinking even in industrial laundries.

New strategies include the treatment and use of process water and the avoidance of microplastics. This is because textiles are one of the largest contributors to microplastic emissions.

Approximately 60% of our clothing consists of synthetic materials, and up to 700,000 fibres of microplastic end up in wastewater with every wash cycle in normal household quantities.[11] When clothes are washed for the first time, a considerable amount of fibrous microplastics are emitted.[12] A large proportion of these microparticles can be retained by using fine-pored particle filters such as curved screens. These filters feature optimum selectivity and rigidity.

And here, too, the smooth mesh surface prevents the fibres from adhering. Moreover, a long service life of the filter is ensured by the excellent backwashing capability.

2.2 Road drains

The hotspots of tyre abrasion are curves, traffic lights, and junctions. Tyre abrasion resulting from drifting, erosion, and stormwater drains can enter bodies of water, accumulating in verges and roadside soils.

This is especially true outside urban centres.[13]

Therefore, the precipitation water enriched with microplastics should, at best, be filtered before it enters the rainwater drains. This is exactly what decentralised treatment systems ensure, which also include road gullies, referred to as filter gullies, with cleaning facilities.[14] By implementing filter and substrate inserts or filter textiles, filter gullies are able to reduce the pollutant load of the water flowing through them in addition to larger solids.

A decisive criterion for selecting suitable filter systems is also the proportion of total suspended solids (TSS). This is due to the fact that a high proportion of pollutants is bound to these nanoparticles (≤ 0.6 µm).[15] Solids such as stones, leaves, and gravel sand can be retained in advance as they pass through a robust wire mesh.

The wire mesh will also serves as a barrier layer for any substrate material used to retain very fine particles.

Unfortunately, only part of the precipitation can be filtered through road drains. At the same time, there is an undetermined amount of seepage water that enters local sewage treatment plants away from gutters and gullies.

On the other hand, water from household appliances and industrial equipment can be directly filtered. The use of efficient filter elements in these areas is therefore examined in more detail in the following.

3. Optimal design of a microfilter

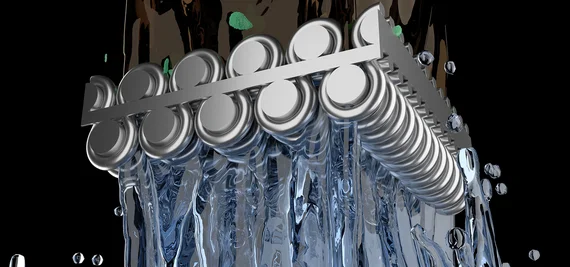

As previously mentioned, the term "microplastics" refers to particles and plastic fragments that fall within a particle size range of 1 µm to 5 mm. Wire mesh filters are an ideal filtration method of reducing the entry of a large proportion of particles into the environment via wastewater.

With a filter fineness adapted to the optimum flow rate, the absolutely uniform mesh geometry of robust and stable metal wire mesh ensures a maximum filter capacity.

Metal wire mesh is created from the predefined combination of warp and weft wires, which result in different mesh patterns depending on the choice of wires and the shape of the mesh. Above all, they are exact geometric structures whose pore sizes and thus the material and flow properties can be precisely defined.

They allow uniform filtering performance over the entire filtering surface and make versatile processing possible. By selecting the type of weave and the material, the mechanical, chemical and physical properties can be adapted to the requirements of each application.

3.2 Success factors of "metal mesh filters in household appliances and industrial plants”

Three success factors play a central role in the planning and development of microfilters for domestic and industrial water filtration. These factors are based on fundamental issues that must not be neglected in the decision-making process to obtain an approach to an optimal solution and go as followed: flow rate, filter fineness, and economy.

The wire mesh filter medium enables you to optimally face these challenges. We will show you in detail how this can be achieved.

The load on the filter as an indicator for the ideal mesh shape

For engineers and developers in the electrical household appliance industry, a high flow rate with precise filtration performance is highly relevant. In order to efficiently filter out a large proportion of all microparticles - including microplastics - from the water before it is discharged into municipal wastewater treatment plants, an optimal filter area is an important indicator in selecting a filter medium and its processing capabilities. For example, while the challenge for the industry lies in the required rigidity of large curved screens and their edging options, engineers are involved in obtaining the best possible solutions within a minimum amount of space when developing household electrical appliances.

Open square or rectangular mesh allows a maximum flow rate and is therefore very suitable for use in household dishwashers and washing machines. In contrast to the large quantities of water produced in industrial plants, they are exposed to a relatively low level of pollution.

Stability is also crucial in the further processing of the generally very flexible wire mesh in order to obtain the largest possible filter area within a minimum amount of space. In other industries as well as in the development of the microfilter in dishwashers, pleating (i.e., folding) of the fabric has proven to be effective. Pleating increases the size of the filter area and thus achieves maximum efficiency.

In laundry equipment, large-area sieve sections are used in which the fine sieve mesh is stabilised by a grid. The production of these screen sections involves gluing the wire mesh to the screen frame or the support grid, for example. If required, the adhesive is food-compliant in accordance with VO (EG) No. 1935/2004 and EU No. 10/2011, heat or acid resistant, and suitable for the use of ultrasound.

High separation efficiency even for the finest of microplastics

The correlation between filter fineness and the filter result is undisputed: the finer the filter mesh, the more foreign particles are retained and the cleaner the water after filtration. The decisive factor in the selection of the right type of mesh is the desired particle size, i.e. the maximum particle size that can pass through the mesh.

The use of a plain Dutch weave has proven effective if the particle size range is within 5 µm and 80 µm. In fact, this weave presses the warp and weft wires as tightly together as possible (zero mesh).

The mesh has a pore channel instead of a mesh opening. In this case, the filter fineness is measured based on the geometric pore size.

As well as its high selectivity and precise filter characteristics, the plain Dutch weave has the following advantages compared to alternative filter materials:

- Flow-optimised mesh structure

- High flow rate

- Easy cleaning

- Low blocking tendency

- Long filter service life

Wire mesh is a good idea in the long term

Obviously, every manufacturer wants to operate as cost-effectively as possible in order to remain attractive vis-a-vis competitors - both in B2B and B2C environments. In the production of dishwashers and washing machines for private use, increased production costs of individual components are clearly noticeable for the end customer, which means that economic production often represents the greatest challenge for all participants in the process chain.

It is no secret that metal wire mesh is not the most inexpensive filter media. Nevertheless, it is extremely attractive from an economic point of view - especially in the filtration of water.

Properties such as stability, robustness, flow rate as well as the exact mesh geometry have already been mentioned. The sustainability aspect is reflected in the excellent regenerability of metal wire mesh - as well as in the recyclability of this medium.

In addition to innovative manufacturing methods, the know-how and experience of the wire mesh experts enable a highly economical production process to be implemented. This begins as early as the theoretical development work.

Whilst in the past, solutions were determined using time-consuming and cost-intensive trial and error procedures, nowadays new filter meshes and their flow rate capacities are determined using highly reliable simulation programs before they are put into practical operation. Initial processing steps directly on the loom as well as the set-up of manufacturing cells to avoid long transportation routes are just as much a part of this as a demand-oriented camera inspection of all mesh blanks. For here too: time is money!

It is the versatility and recyclability that makes the wire mesh filter medium the ideal solution for domestic and industrial water filtration. Versatility in particular requires an overview of all options and your individual requirements.

With decades of experience in the manufacturing and further processing of metal wire mesh, the experts at Haver & Boecker know what is important when it comes to fabricating components for the filtration of microparticles. In addition to industry-leading precision and care, the company's actions in all areas of wire mesh production are hallmarked above all by an extraordinary innovative spirit.

So please do not hesitate to approach us with your project ideas and challenges. Let’s work together to make the world a bit cleaner!

Sources (November 2022):

[1] cf. Jessica von Blazekovic: "Was ist Plastik" (What is Plastic), FAZ, September 2018

[2] cf. Welt.de: "Jeder von uns isst eine Kreditkarte pro Woche" (Each of us eats one credit card per week), June 2019

[3] cf. Ecologic Institut gemeinnützige GmbH: "Kernbotschaften" (Key messages), focus of BMBF research "Plastik in der Umwelt" (Plastics in the environment), July 2022, page 6

[4] cf. Fraunhofer Umsicht: "Daten und Fakten Mikroplastik" (Microplastics: facts and figures), February 2019

[5] cf. ebd.

[6] cf. Ecologic Institut gemeinnützige GmbH: "Kernbotschaften" (Key messages), focus of BMBF research "Plastik in der Umwelt" (Plastics in the environment), July 2022, page 8 et seq.

[7] cf. ebd., page 16

[8] cf. WellBlue: "Mikroplastik im Trinkwasser" (Microplastics in drinking water), pie chart, April 2021

[9] cf. Greenpeace: "Mikrofasern aus Kleidungsstücken belasten die Ozeane" (Microfibres from clothing pollute the oceans), February 2021

[10] cf. Ecologic Institut gemeinnützige GmbH: "Kernbotschaften" [Key messages], focus of BMBF research "Plastik in der Umwelt" (Plastics in the environment), July 2022, page 8

[11] cf. ebd., page 9

[12] cf. MKULNV VRW: "Niederschlagsentwässerung von Verkehrsflächen" (Rainwater drainage from traffic areas), not dated, page 67

[13] cf. Abwasser Analysezentrum: "Abfiltrierbare Stoffe" (Total suspended solids), not dated