HAVER POROSTAR® in chromatography

Maintaining the stability with woven wire cloth laminated panels in HPLC

High Performance Liquid Chromatography (HPLC) is one of the most important types of chromatography. The liquid chromatography process involves separating mixtures of substances in order to identify their components and determine their content. In addition to analytical purposes, it is also used in the chemical industry to filter out specific substances in a product (e.g. in the production of insulin).

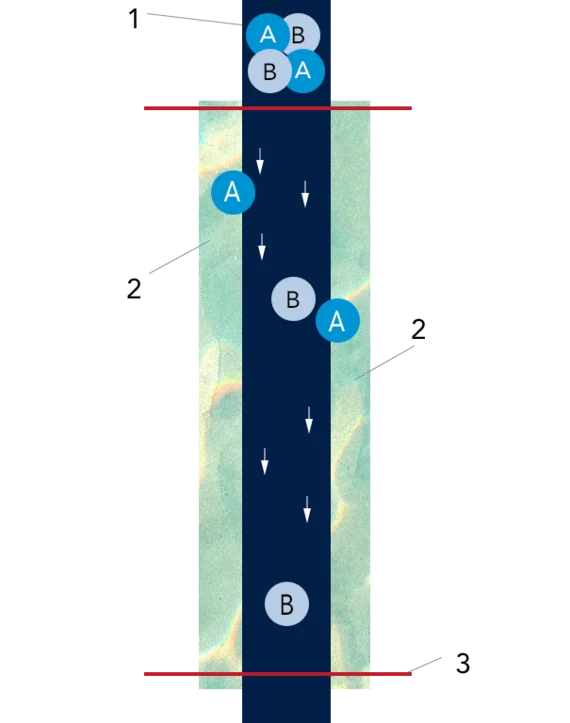

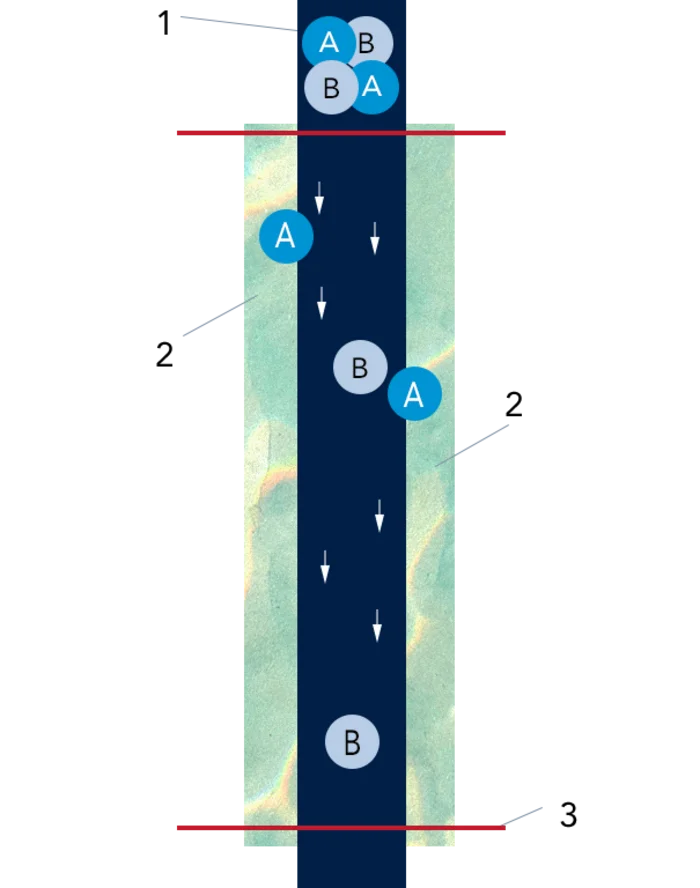

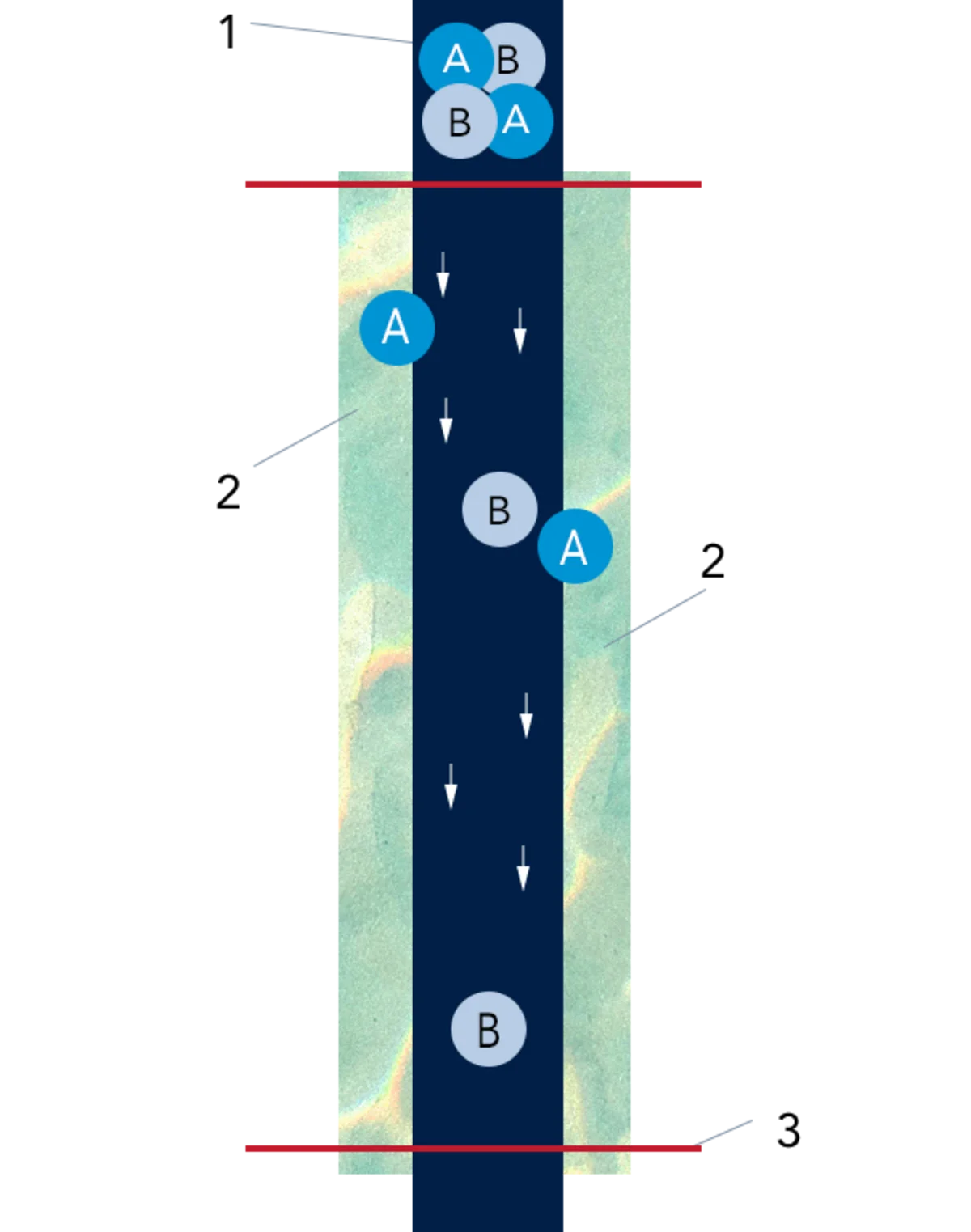

Put simply, chromatography involves a mobile phase and a stationary phase, both of which are located in a chromatography column.

In HPLC, the mixture of substances to be separated is injected into a flowing solvent (eluent) and in this mobile phase is pumped under pressure through an immobile stationary phase. Depending on the interaction with the individual substances of the stationary phase, component A of a mixture is detached and dissolved out (elution). In analytical applications, a detector then measures the delayed input of the separated components and displays the result in the form of a chromatogram.

The stationary phase comprises a gel, a solid (sorbent) or a liquid (separating liquid).

The aim is to reliably immobilise this phase with the aid of a so-called chromatography frit and yet enable a uniform flow of the mobile phase.

The solution

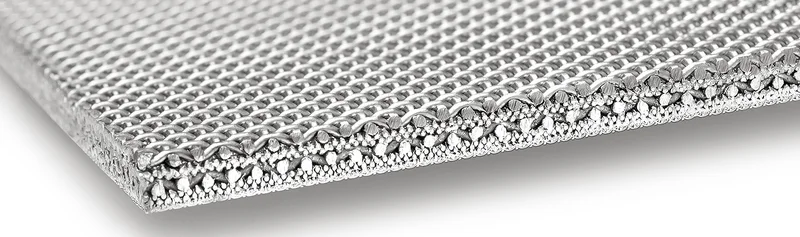

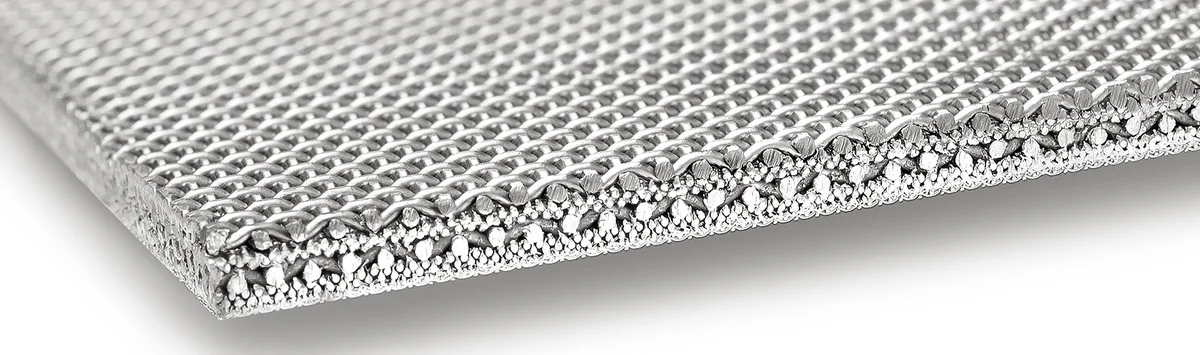

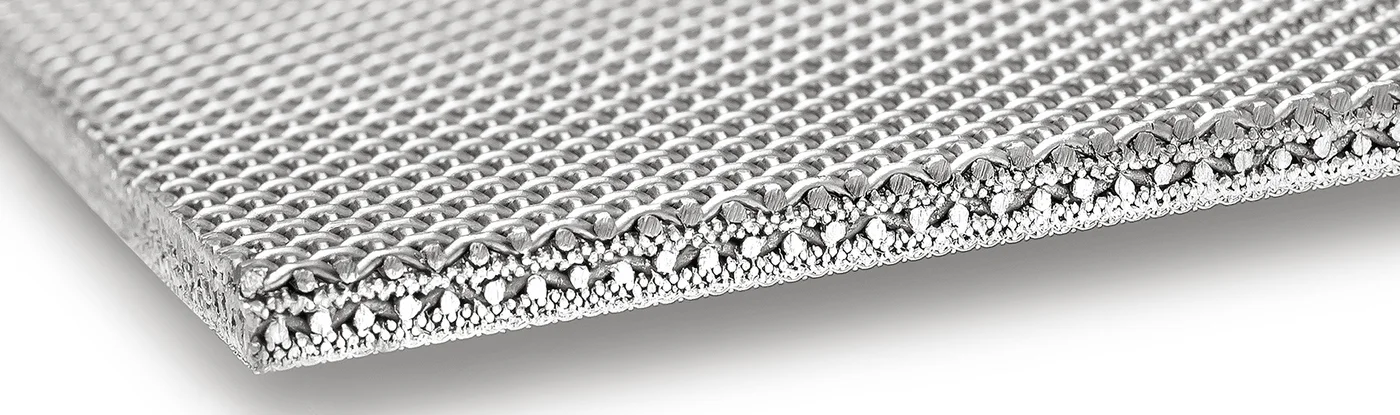

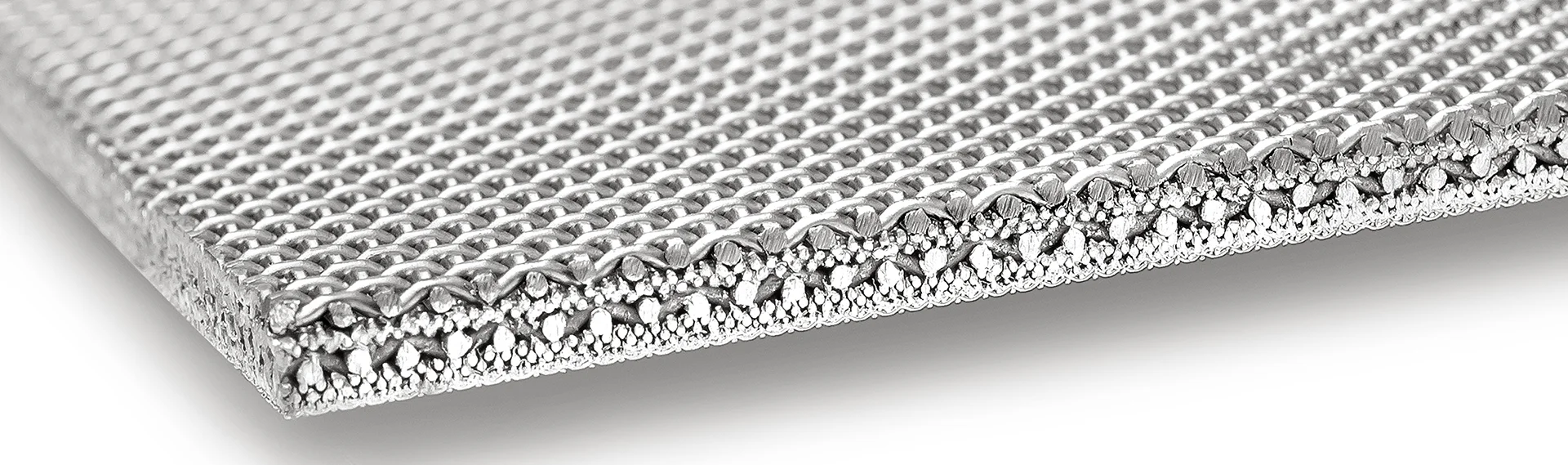

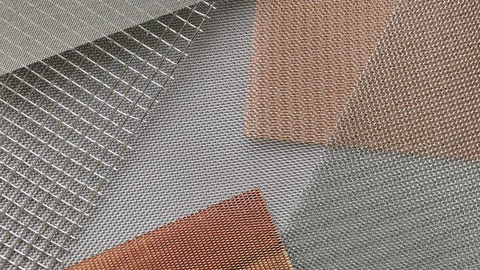

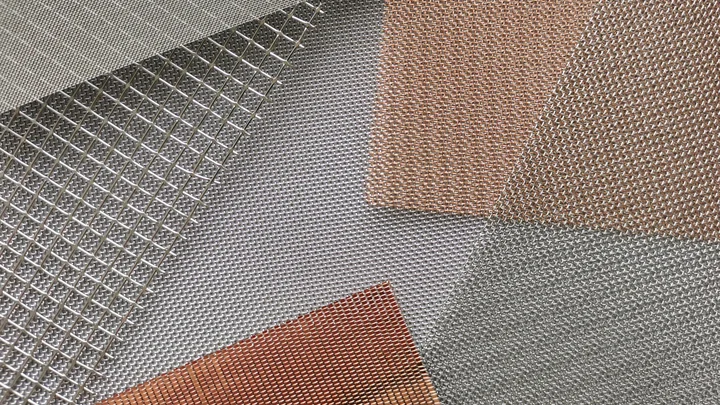

HAVER POROSTAR® woven wire cloth laminated panels form the chromatography frits, which are positioned at the beginning and end of the stationary phase to provide perfect support. They are characterised by their stability and precise selectivity, which are essential for reliable cohesion of the stationary phase. They simultaneously optimise the flow of the mobile phase. Together with the ability to block undesirable contaminants, this leads to consistently high elution and therefore precise and repeatable results.

Everything can be planned - in every dimension

As a filter medium, HAVER POROSTAR® achieves foreign particle-free filtration of particles smaller than 1 µm. With diameters ranging from 2.4 mm to 3 metres, the filter discs used here vary not only as regards the dimensions.

The type and structure of each cloth layer of the composite as well as the number of layers also vary and are defined according to the required pore size and other individual process parameters. The aim here is to achieve a balance between separation efficiency and flow rate. The thickness and density of the chromatography frits are also decisive.

No fluttering or sagging of the cloth

The layer of filter mesh is responsible for the precise selectivity. In order to withstand high pressures as well as mechanical, thermal and chemical processes, the mesh is firmly embedded in a composite with stronger layers of mesh.

The required corrosion resistance is achieved by selecting the ideal material to suit the chromatography process.

Stainless steels such as Hastelloy C22, 1.4404 and 1.4539 have proven to be effective here.

Cleaning, repair and replacement of HAVER POROSTAR® woven wire cloth laminated panels

The excellent regenerability of the woven wire cloth laminated panels lends itself to integration into a cleaning routine to remove any dirt particles and contaminants, which would falsify the results later. Depending on the application, a mild cleaning agent, a soft brush, pressurised air or ultrasound are suitable for this purpose. Thanks to the robustness of the laminated panels, using high-pressure washers (fan nozzles) of up to 200 bar have also proven effective in practice.

Further reasons for repair or replacement:

- Abnormalities in the chromatogram or increased pressure during HPLC coupled with reduced material flow are signs of permanent blockage of the frit, which will necessitate replacement of the entire woven wire cloth laminated panel or part of the affected area. Replacement panels with exactly the same specifications are available in this instance. Flush seams, which have no negative impact on the separation results are the hallmark of our outstanding welding expertise.

- Leakage leading to product loss during the analysis process may be the result of damage to the laminated panel or deformation of the frit. A repair could also remedy the situation in these cases.

- Changes in industry standards and manufacturer specifications justify the complete replacement of the filter elements.

Decisive for HAVER POROSTAR®

High temperatures, risk of corrosion, high loads and pressures as well as the demand for a continuously high throughput and a sustainable production process are indicative for choosing HAVER POROSTAR® woven wire cloth laminated panels in HPLC. Although the acquisition costs are in the high-end price range, thanks to their reusability and long-term process integration implementing these laminated panels nevertheless pays off in the long term.

But above all, HAVER POROSTAR® minimises or even eliminates the loss of the significantly more valuable stationary phase.