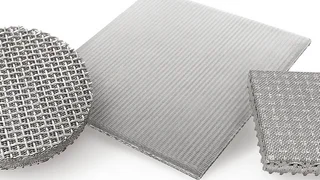

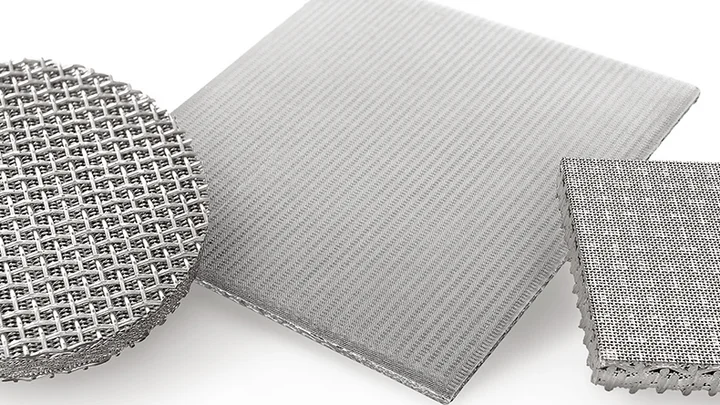

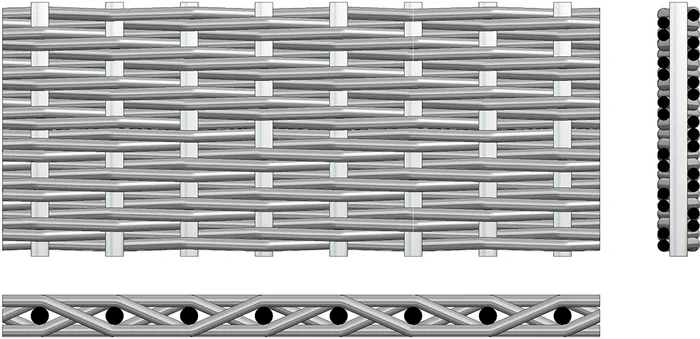

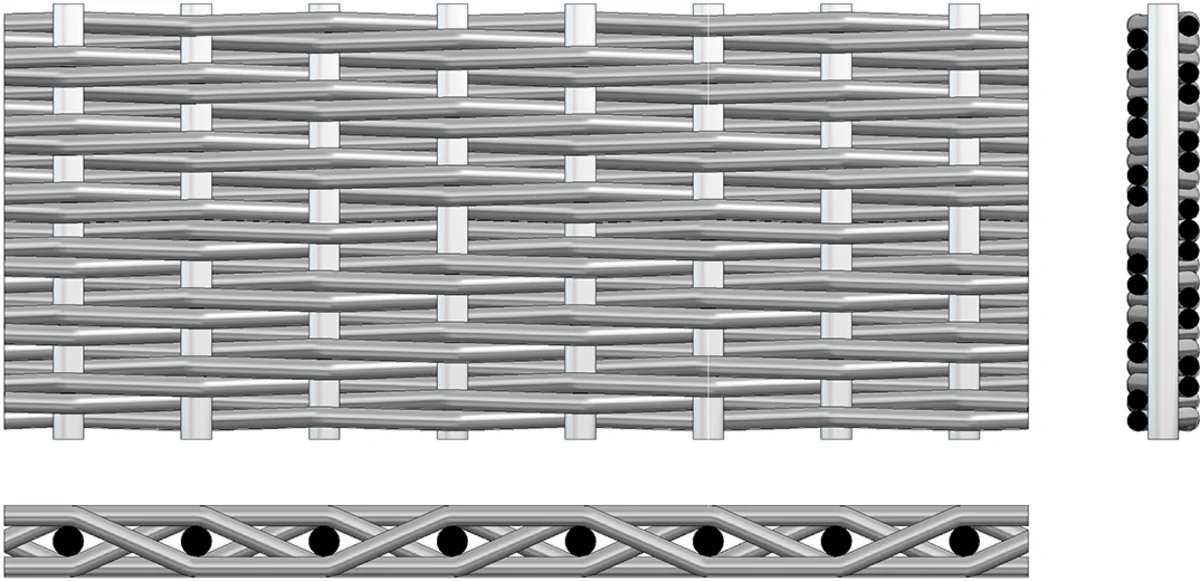

Our MINIMESH® filter mesh variety

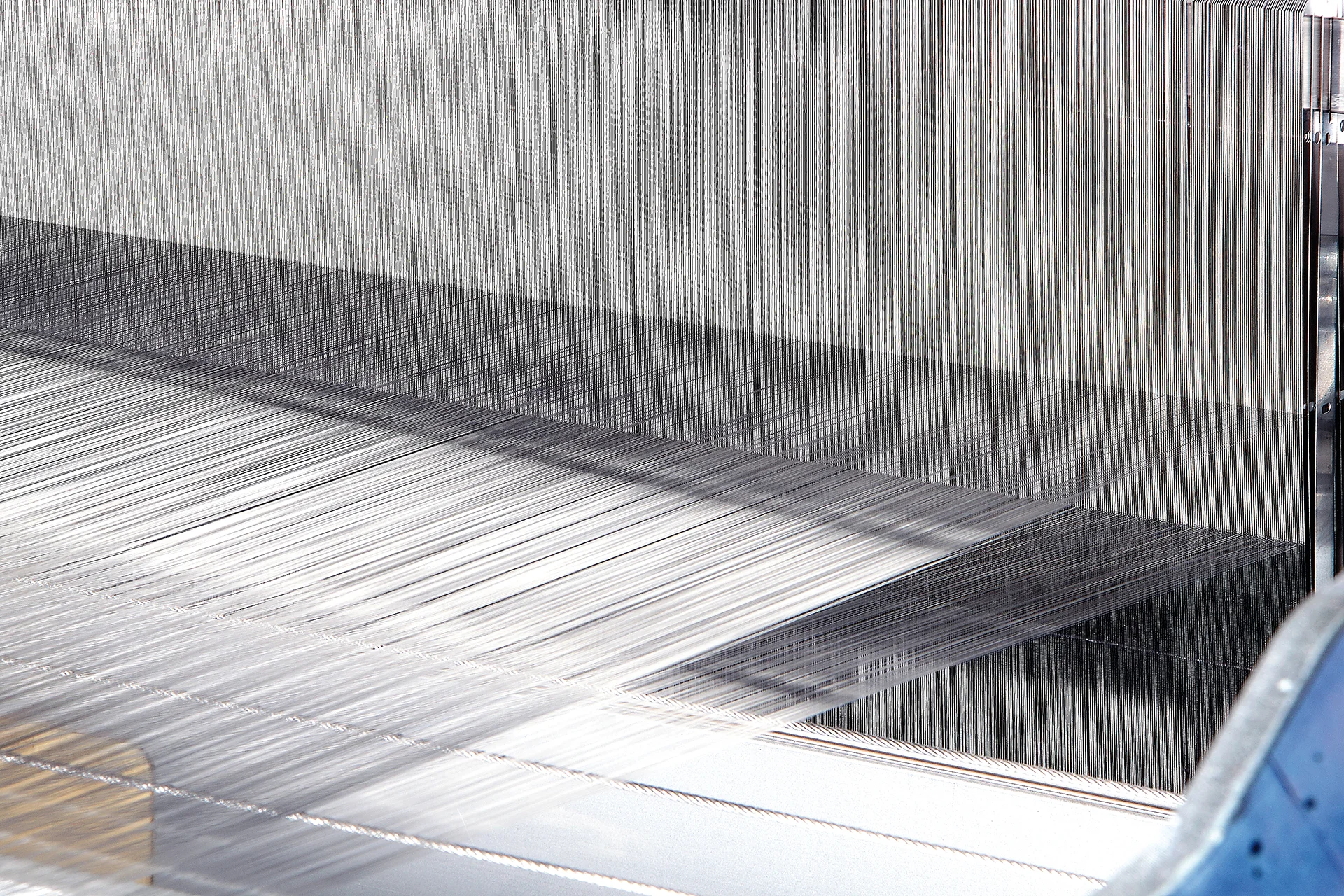

Precise, clean, efficient

The filter properties of MINIMESH® S-Metal Filter Cloth can be precisely adjusted to the respective area of application. Even after processing and in extremely shaped areas, the predetermined characteristic is retained. Thus industrial filtration processes run in a permanently stable, precise, clean, energy-efficient and overall economical manner.

Excellent: Higher selectivity due to precision pores

MINIMESH® S-Metal Filter Cloth specifications have an optimised pore geometry with a precisely determined pore size. As a result, they attain a precise cut point and dimensional stability previously unattainable.

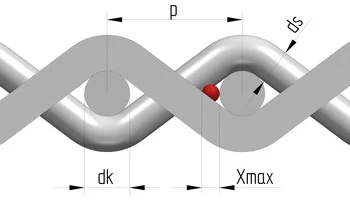

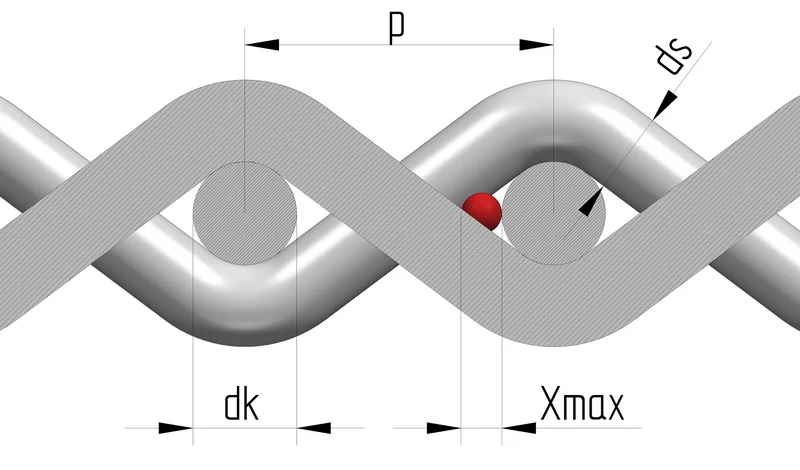

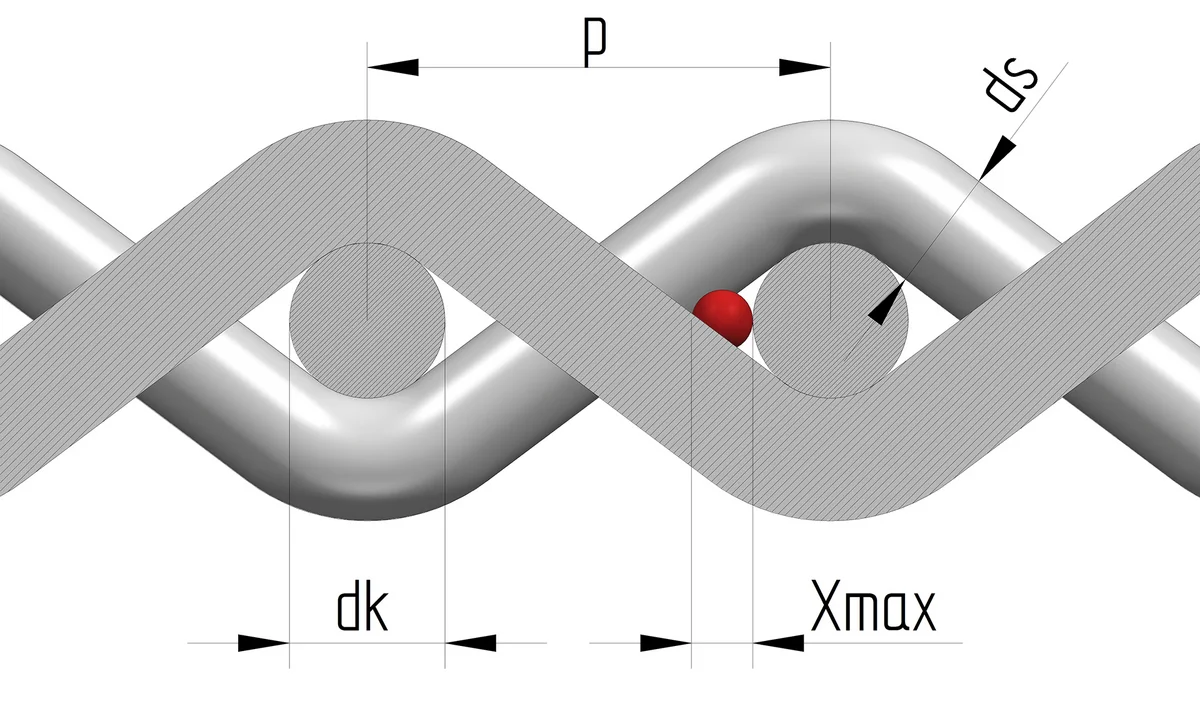

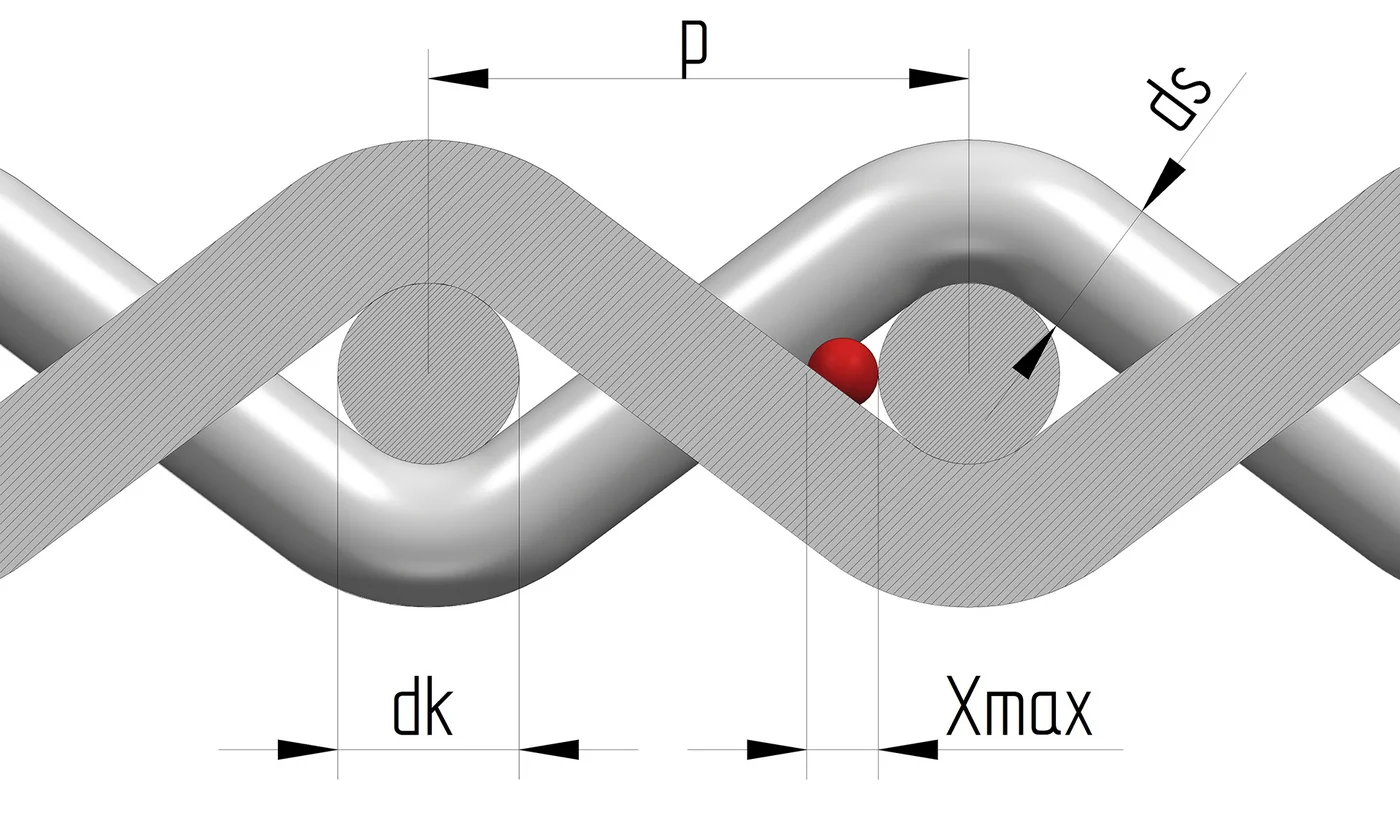

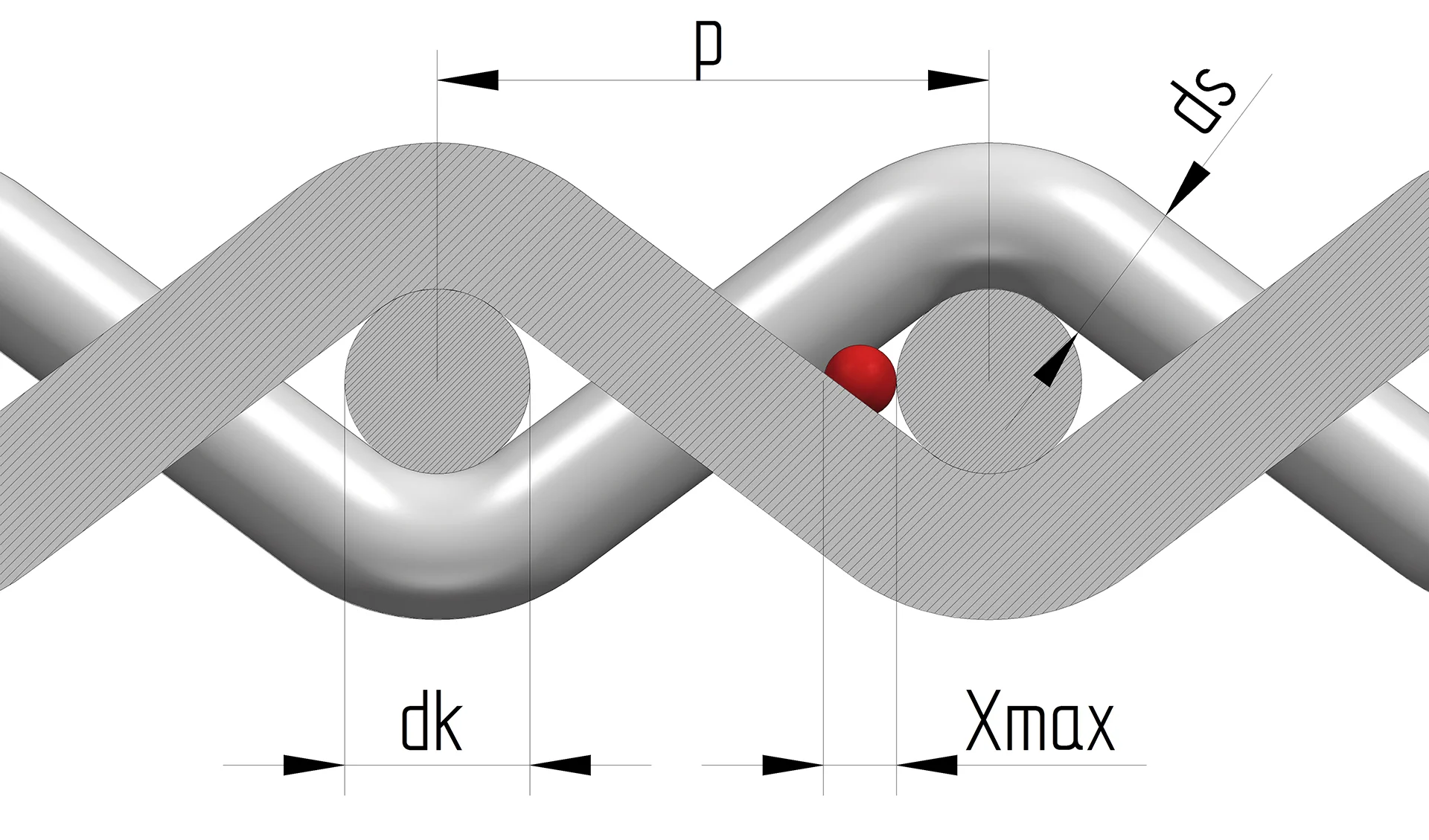

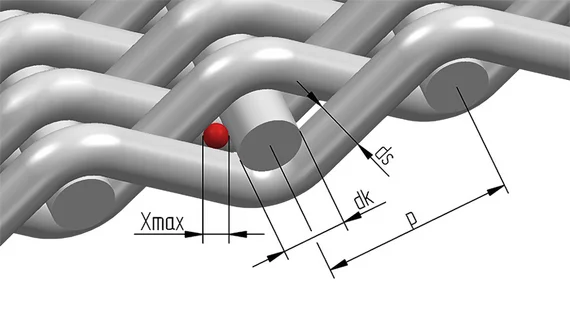

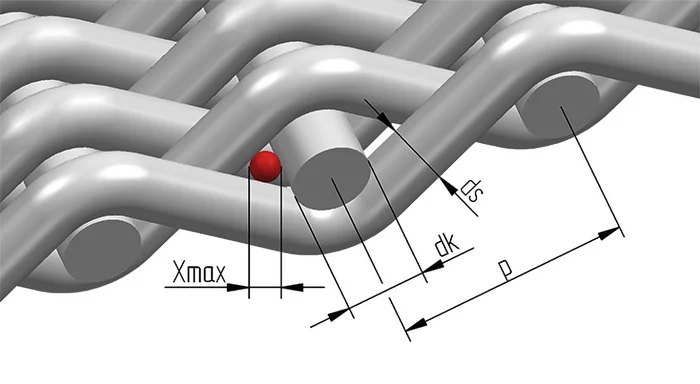

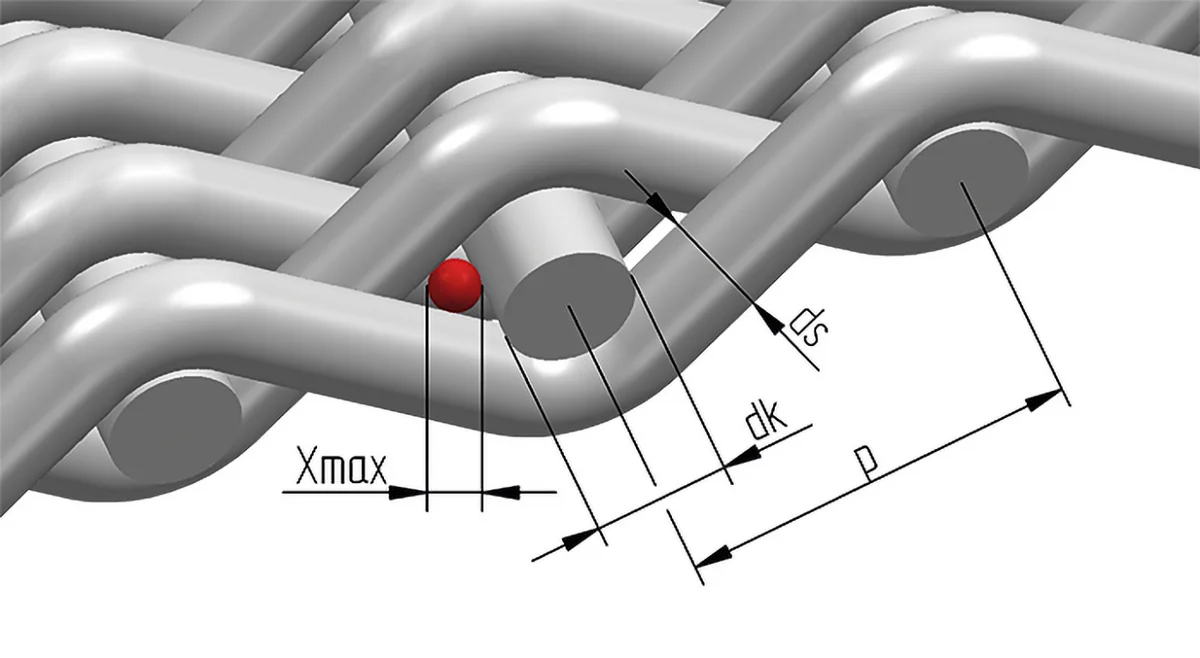

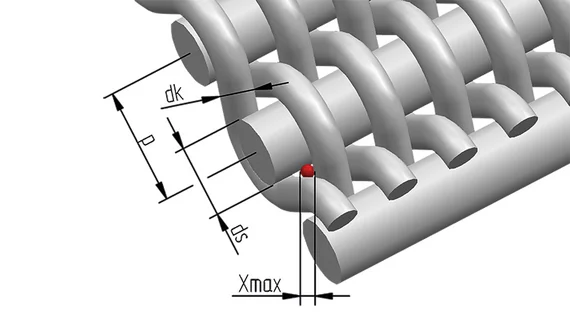

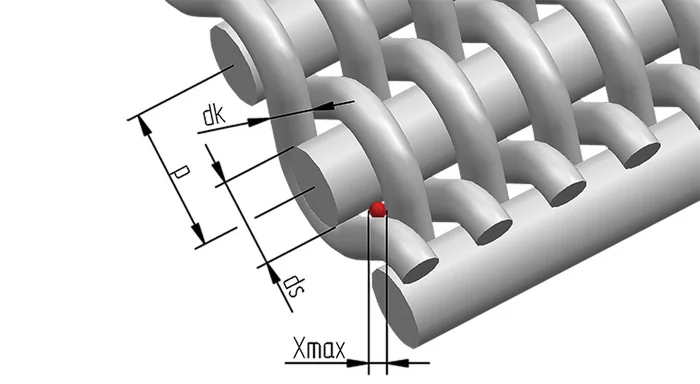

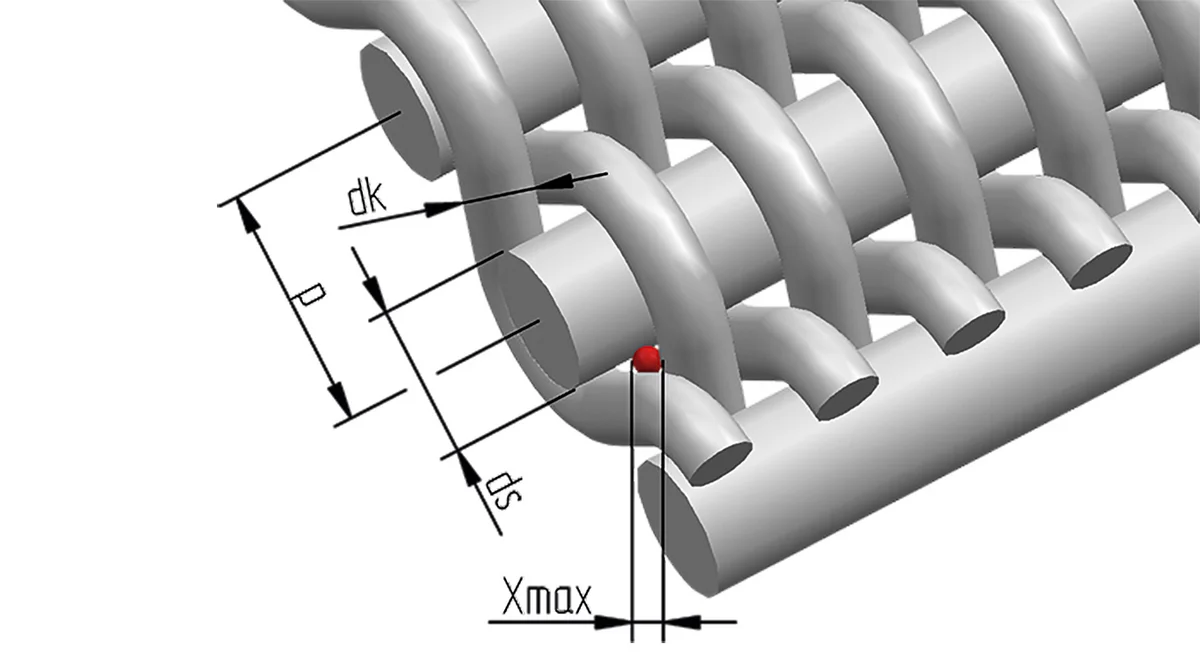

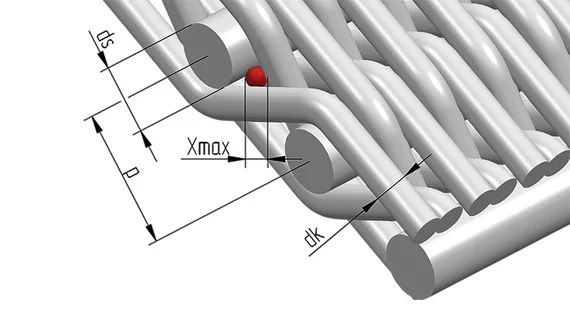

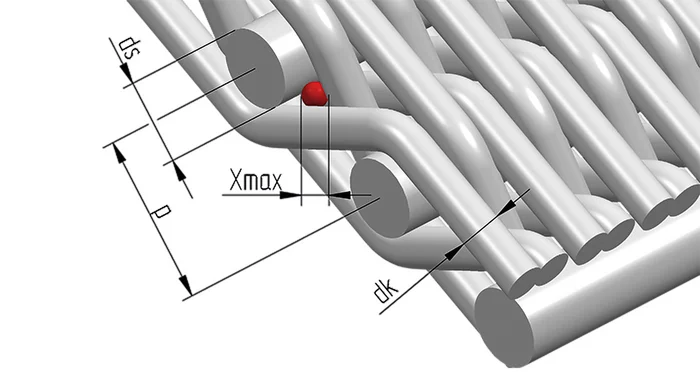

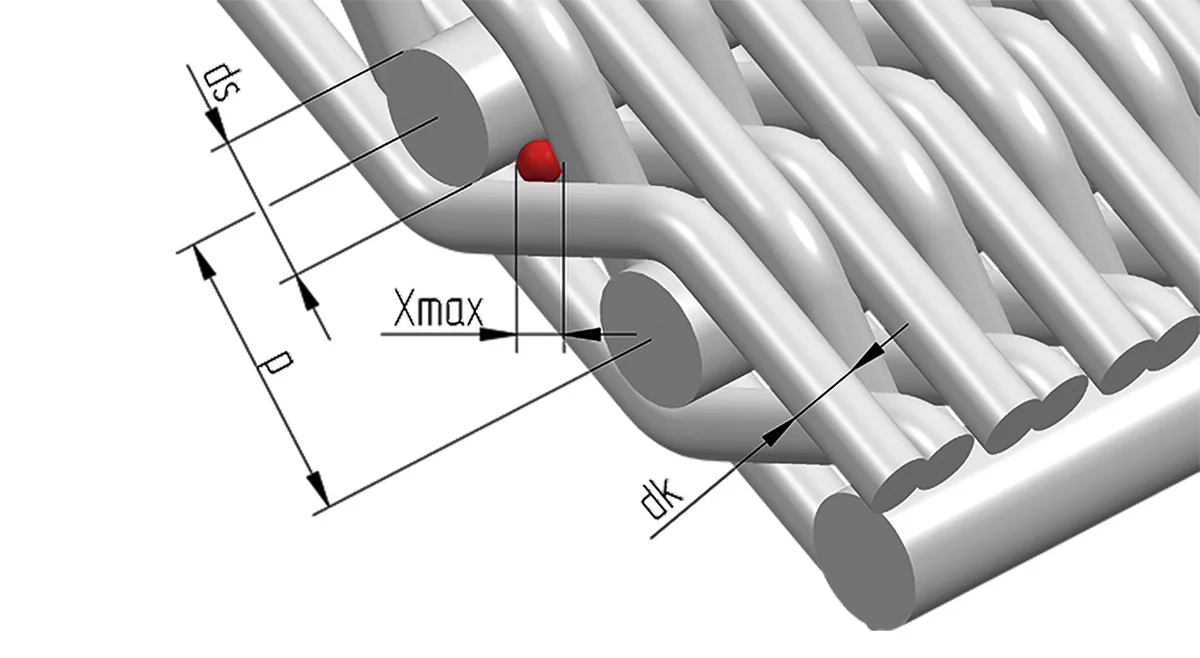

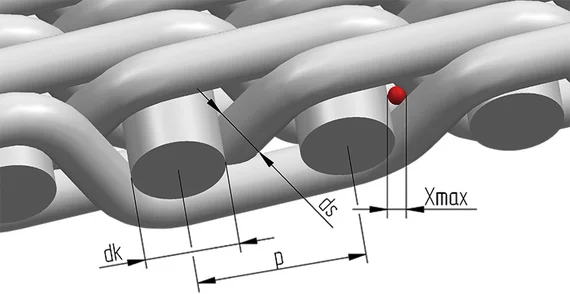

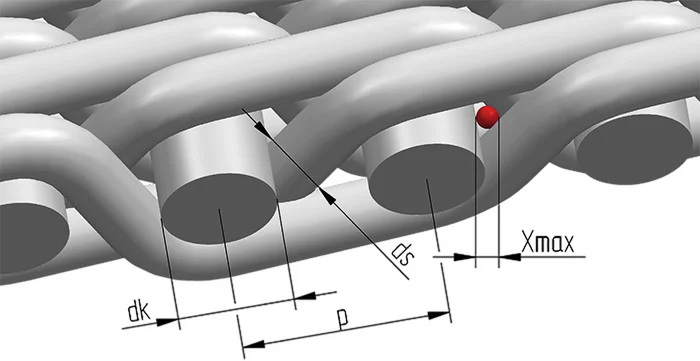

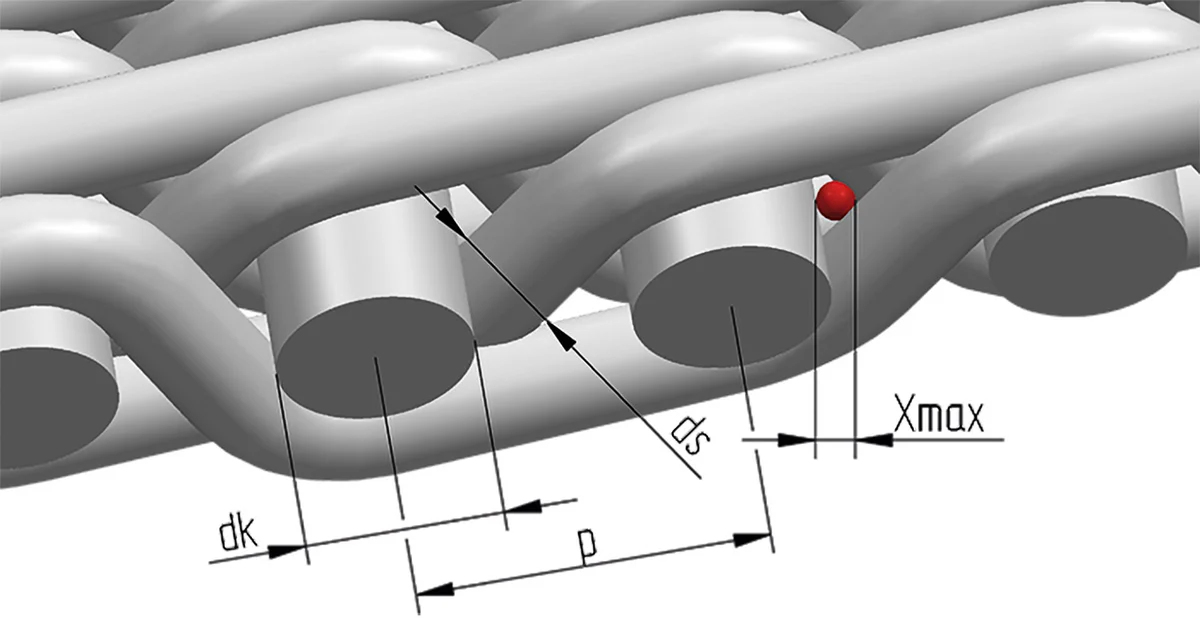

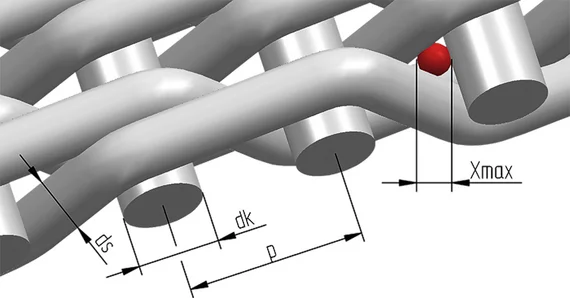

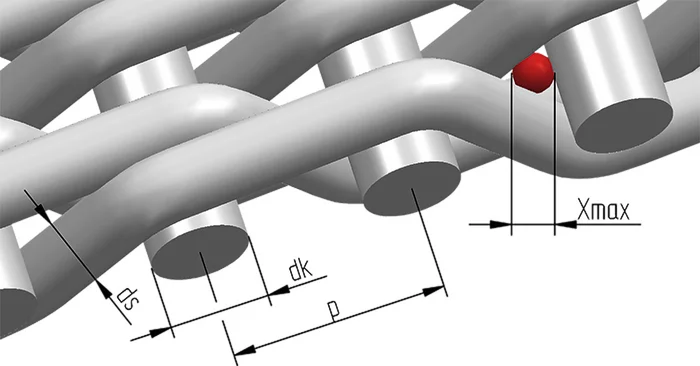

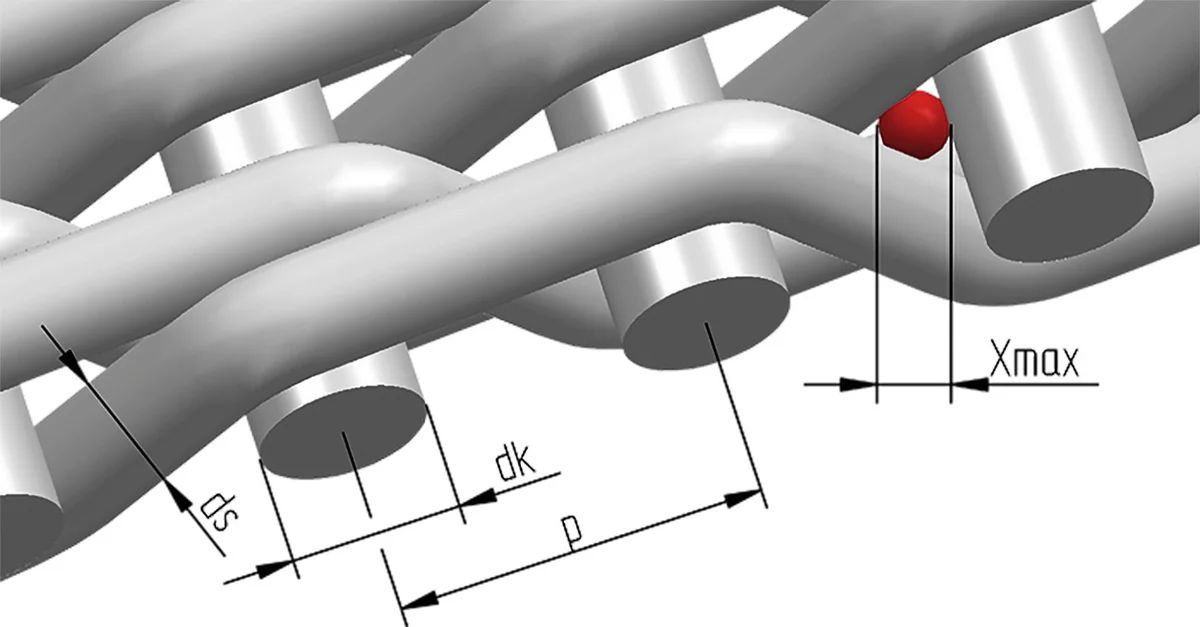

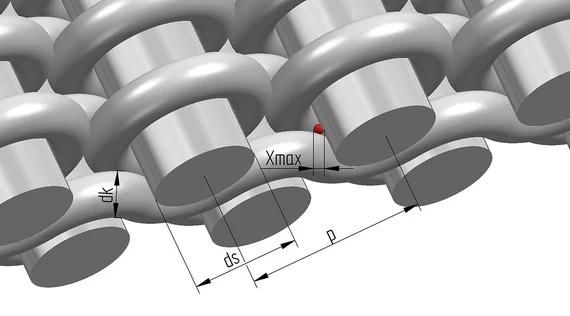

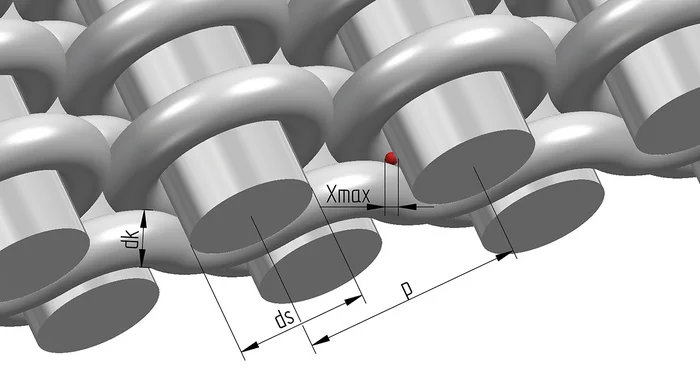

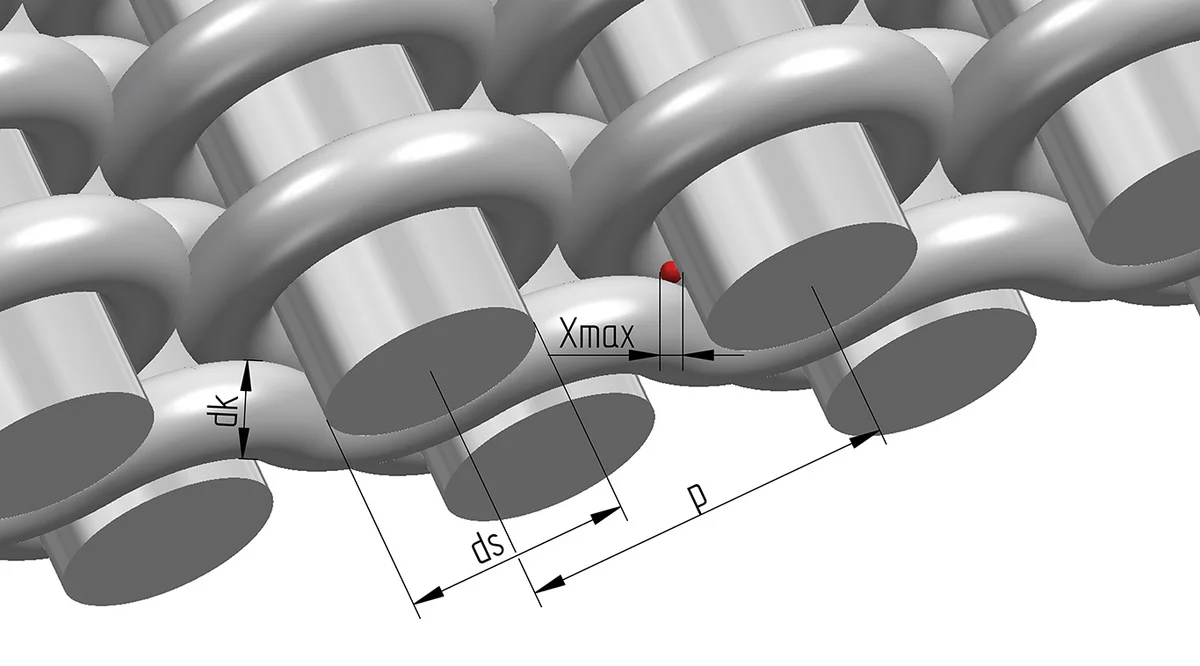

For the geometric pore, a characteristic value is determined that describes the diameter of a sphere that can just pass through the filter cloth. HAVER & BOECKER gives the value Xmax (= maximum pore size) as a reference value for the pore size.

The pressure drop coefficient for air in a laminar flow is used to evaluate permeability. Haver & Boecker developed the mathematical equations on which the procedures are based in cooperation with the University of Stuttgart.

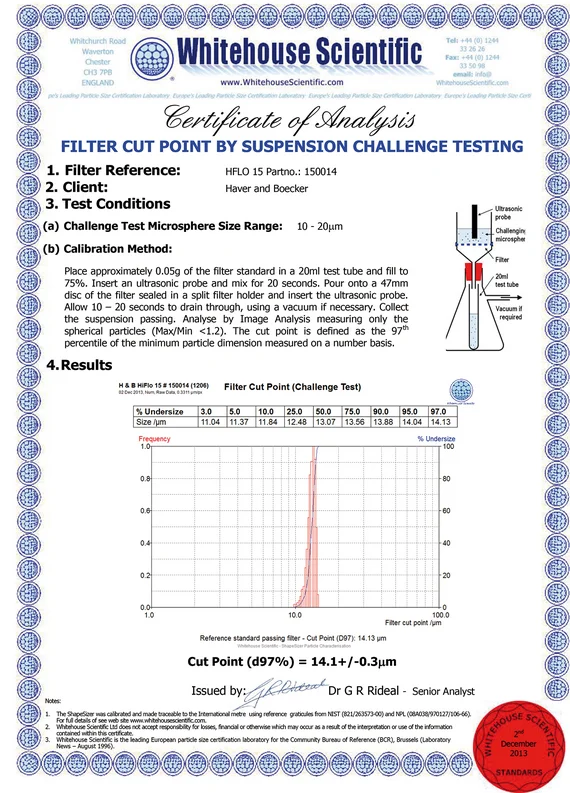

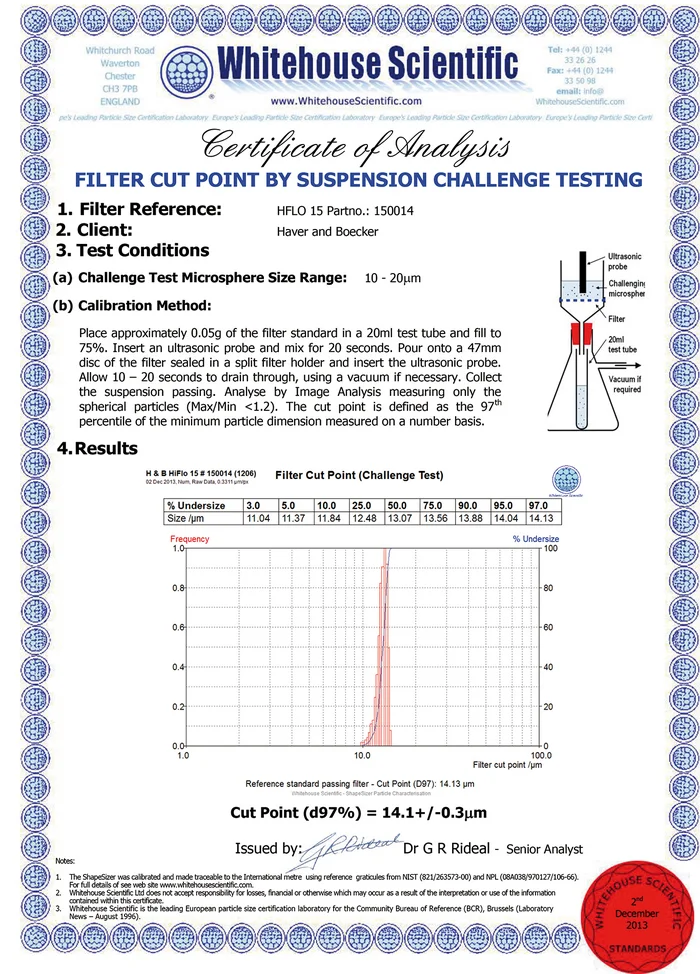

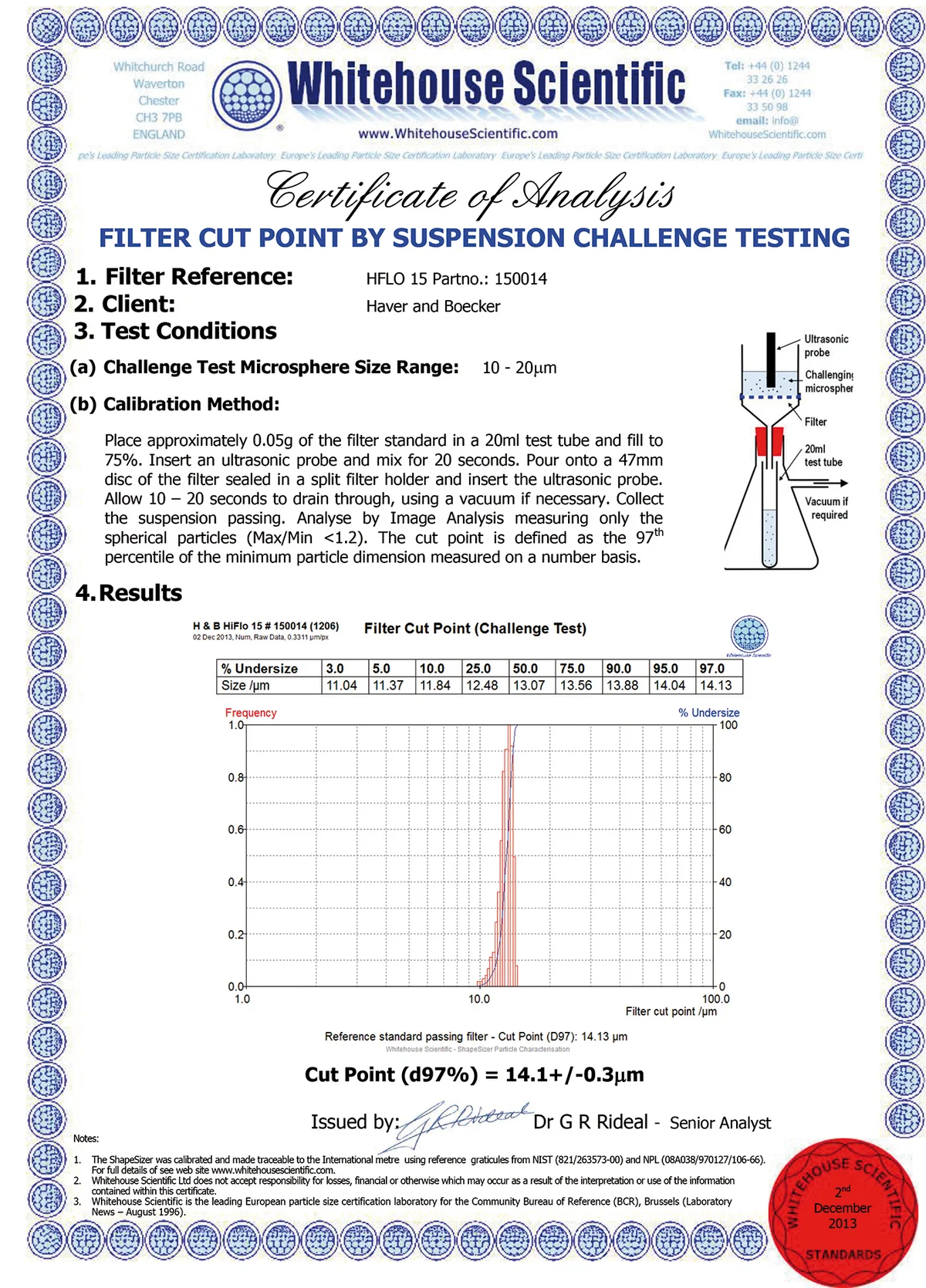

The mathematical formulae were checked and confirmed using known measurement methods to determine the pore size and flow-through. The maximum pore size was determined using the glass bead test. In addition, Haver & Boecker applies the "Bubble Point Method" according to SAE ARP 901 as part of its quality assurance.

The independent, internationally renowned test institute WHITEHOUSE SCIENTIFIC confirms the outstanding filter characteristics of the MINIMESH® S generation with "precision pores".

A clean solution: Improved purging and reduced blockage

The filter effect and flow capacity of MINIMESH® S-Metal Filter Cloth stay considerably longer compared to other filter media. The tendency to block is lower, cleaning is easier. This leads to permanently precise filtration and longer service lives of the filter media used.

Verification of these properties is carried out in cooperation with the Institute for Mechanical Process Engineering, IMVT. These include air flow-through measurement, determination of the fractional separation efficiency (FAG), the dirt absorption capacity with test dust according to ISO 12103 and the cleaning behaviour measured in accordance with VDI 3926 Type 2. HAVER & BOECKER uses an automatic residual contamination analysis system to verify the high purity of MINIMESH® S-Metal Filter Cloths.

Best materials for best meshes

MINIMESH® S-Metal Filter Cloths are mainly made out of stainless steel, for example 1.4301, 1.4306, 1.4401 and 1.4404. In addition, if required, also from other materials that have the metallurgical properties required for extremely thin wires.

Learn more about the materials for wire mesh here.

Pore size range:

- 30 µm to 300 µm

Properties

- Slight cleaning

- A narrow pore distribution

- High flow properties with a good mechanical strength

Example applications

- A wide range of applications from filtration of air to drinking water, through to hydraulic oil

- Use in lightning protection and sound insulation systems

- Plastic extrusion

- Gas exploration

Pore size range:

- 15 µm to 40 µm

Properties

- A high flow rate with small pore sizes

- Easy to clean and a good backwashability

- A very narrow pore size distribution

Example applications

- Filtration of air at high volume flows and low dirt loads

- Use as an absolute filter in lubricating oil circuits and fuel systems

Pore size range:

- 7 µm to 120 µm

Properties

- Mechanically robust

- A narrow pore distribution

- An exact degree of separation

Example applications

- Protective filter for an injection system

- Drinking water treatment

- Gas and oil exploration

- Blood plasma filtration

- Versatile use up to the filtration of viscous substances, e.g. cocoa butter

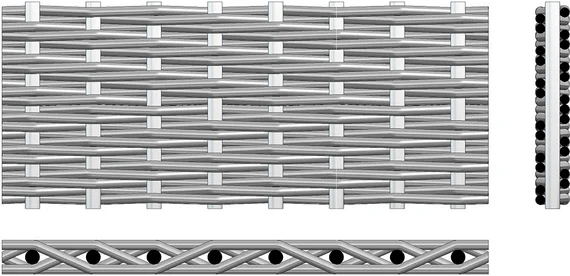

Pore size range:

- 13 µm to 55 µm

Properties

- A good flow rate

- Mechanically particularly robust with zig-zag binding

Example applications

- Flue gas filtration

- Plastic extrusion

- A protective filter for additive admixtures in injection systems

*Patented: US020110290369, CH000000702351

Pore size range:

- calibratable from 5 µm to 40 µm

Properties

- Double the flow rate with the same pore size as comparable filter braids

- Excellent selectivity and stability

- Corrosion and temperature-resistant special materials

- An optimum dirt absorption and cleaning capacity

Example applications

- Sand control screens

- Crude oil filtration

- Ballast water filtration

- Fine filtration in the chemical and pharmaceutical industry