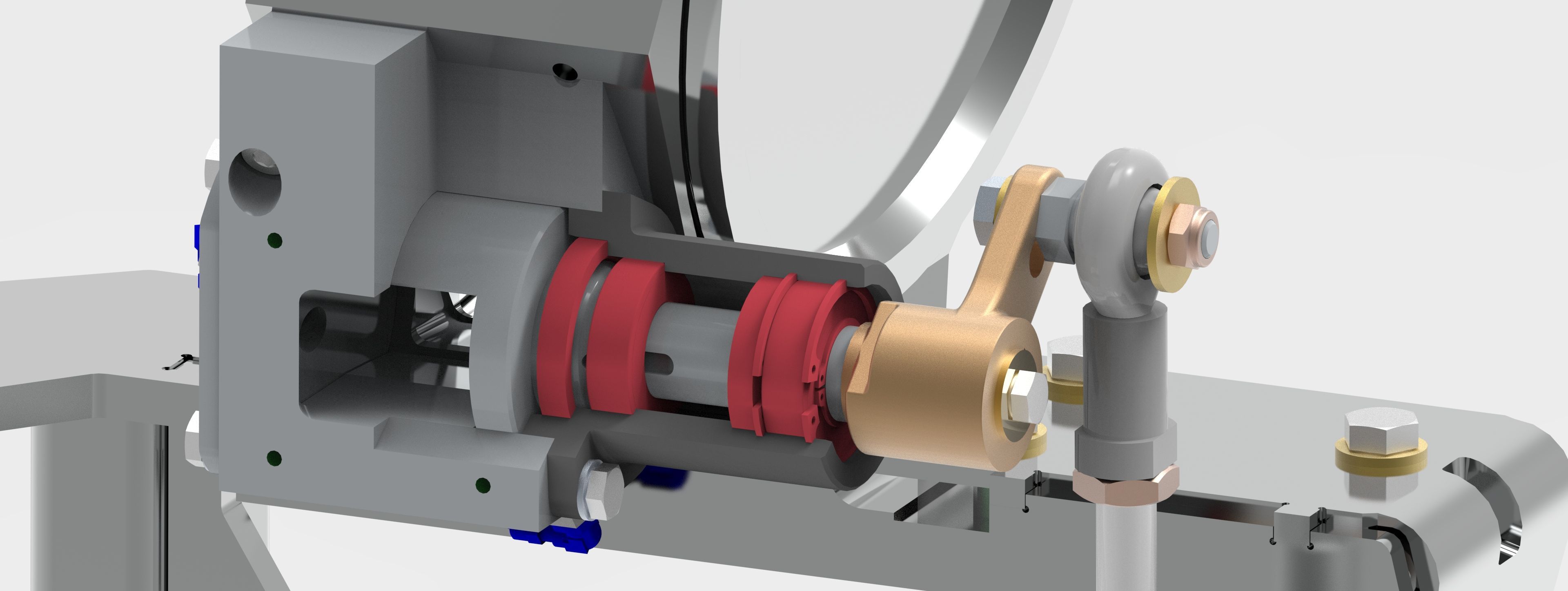

The ROTO-LOCK® gasket set

For continuous performance

You have decided to equip your HAVER & BOECKER packing machine with our ROTO-LOCK® dosing unit. Your decision to use this dosing system was far-sighted: you are ensuring a clean and healthy work environment for your team and the careful use of our valuable resources - thanks to a high level of product protection. ROTO-LOCK® is the patented result of our engineering expertise - the innovative solution for clean and precise dosing in your filling process.

The ROTO-LOCK® is a unique achievement for the dosing process and it offers you reduced maintenance and long-lasting reliability for the entire filling process. The ROTO-LOCK’s shaft seals and deep groove ball bearings are wear parts that should be replaced regularly as a preventative measure. To prevent unforeseen bearing damage!

Bearing

Snap ring

Sealing ring

Filling box

![[Translate to English:]](/fileadmin/HaverBoecker/DieMaschinenfabrik/01_graphic/Profilfotos/Eva-Ellebracht.png)