Manufactured and refined

Everything from a single source.

We produce Haver screen printing mesh from selected wire qualities out of high-quality stainless steel alloys and on weaving machines that our mechanical engineering specialists develop and build themselves. Precisely defined cloth thicknesses, very high mesh accuracies and tight tolerances as well as precisely defined print layer thicknesses permit outstanding print results. After the weaving process, the mesh is carefully cleaned in a specially developed process without affecting the physical properties.

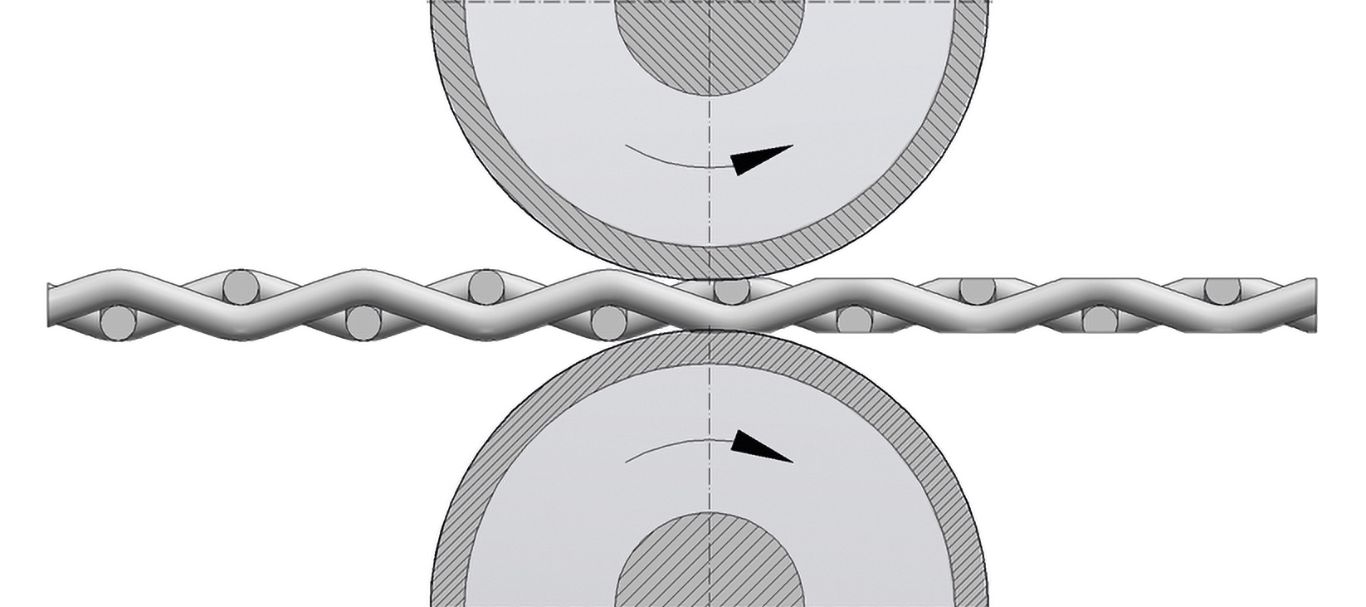

Calendering – precisely according to your wishes

During calendering, the fabric is reduced to a fixed thickness between two steel rollers. This process stabilises the mesh and makes it more resistant to displacement. At the same time, smooth, particularly even, surfaces are created.

With calendered mesh, you achieve the exact ink application required for your application. The smoothed surface not only reduces deviations in print layer thickness from print to print and squeegee stroke to squeegee stroke, but also reduces squeegee wear.

Haver & Boecker offers two calender standards and also calender grades tailored to your individual requirements.

-

Test Report 2.2 - Screen Printing Mesh File Size: 155 KB

Maximum calendering

The mesh is reduced to a thickness that is up to 30 percent less than twice the diameter of the single wire:

D = 2 x d x 0.7.

This enables the maximum possible thickness reduction of the wire cloth without it being deformed. The mesh openings remain unchanged, the fabric takes on a foil-like character.

![[Translate to English:] Siebdruckgewebe](/fileadmin/HaverBoecker/DieDrahtweber/01_graphic/Profilbilder/Profilbild-SD.png)