HAVER POROSTAR® - filter elements

Metal wire mesh laminated panels: stable, precise, custom-made

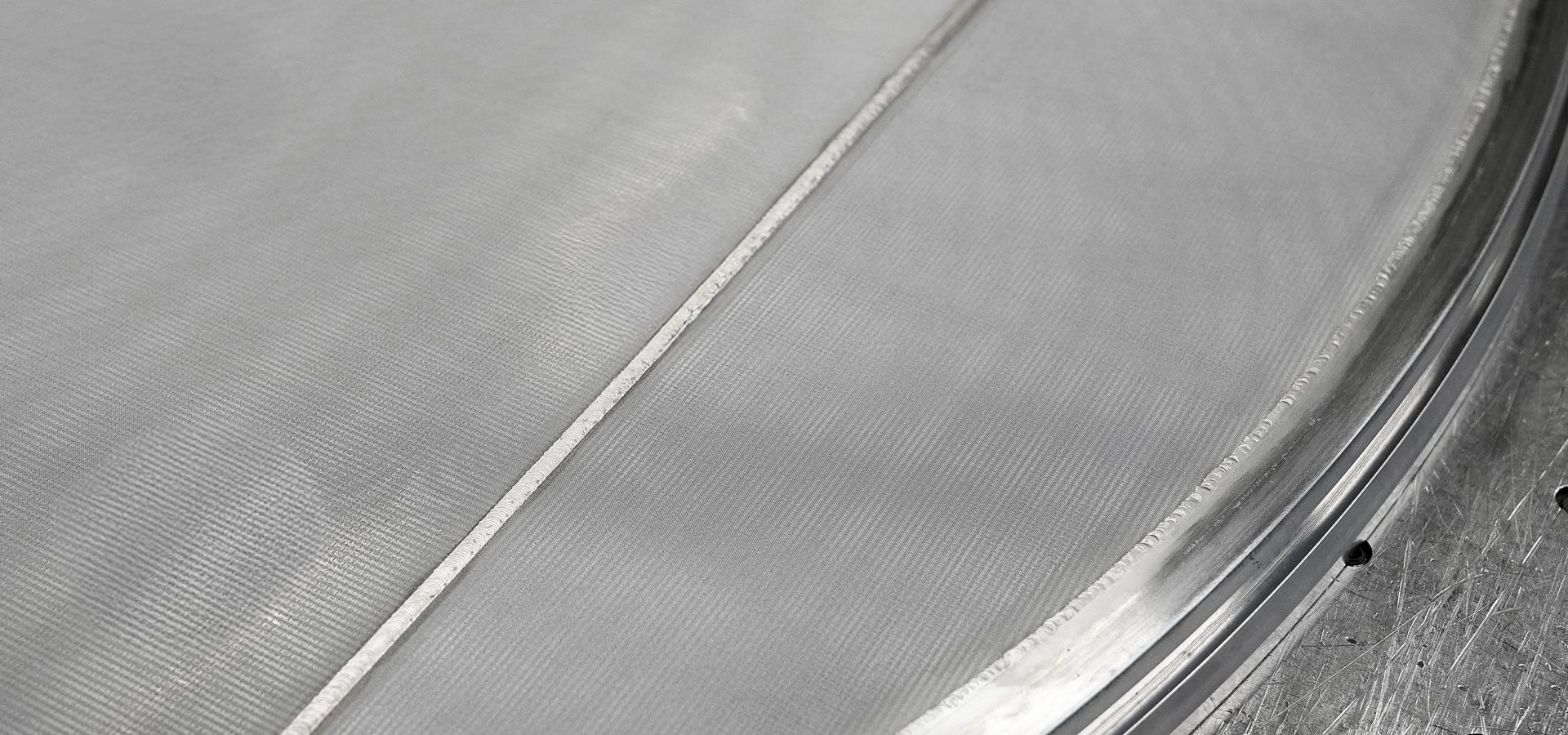

POROSTAR® filter elements made from metal wire mesh laminated panels consist of a large number of wire mesh layers that are firmly bonded together by diffusion. After initial heat treatment, the mesh laminates are sintered a second time. This duo-sintering technique leads to a firm connection of the layers.

Diverse areas of application

As a filter medium, HAVER POROSTAR® enables you to achieve foreign particle-free filtration in the range < 1 µm to 200 µm. No particles come loose, even at the maximum operating pressure.

Metal wire mesh laminated panels / mesh laminates are used as filter cartridges, in centrifuges and nutsche filter systems. HAVER POROSTAR® has proven itself for solid-liquid filtration and hot gas filtration in the following industries:

Duo sintering technology

This is how strong connections are made

The duo-sintering technology results in the diffusion of all wires in contact with each other without changing the geometric structure of the individual cloth layers. The result is a stable, porous filter medium with characteristics that can be determined in advance:

- Pore size

- Pore distribution

- Porosity

- Permeability

The mesh layers are put together in such a way that they optimally meet your filtration requirements. HAVER POROSTAR® can be formed and welded. We can also connect the mesh laminates with additional support materials such as perforated metal sheets.

Formats and materials

We manufacture HAVER POROSTAR® in sheet formats in the standard format 1,200 mm x 1,200 mm up to a maximum of 1,520 mm x 1,900 mm or 1,400 mm x 2,050 mm without a weld seam.

We use modern welding methods to join the panels to create the desired larger formats. For example, filter plates with diameters larger than 1,200 mm or filter cylinders larger than 400 mm in diameter are produced.

The material used is mainly chrome-nickel-molybdenum steel, 1.4404 = AISI 316-L. Various special alloys are also used.

POROSTAR® COMBI

is suitable for the highest differential pressure load, even in counterflow. In this process, the metal wire mesh and perforated plate are joined together by sintering to form a single unit. POROSTAR® COMBI is available in a STANDARD version as well as in the special versions LIGHT or HIFLO. The number of mesh layers and the thickness of the perforated plate are variable.

Customised POROSTAR® tandem-filter candles

Cylindrical filters for process gas filtration

The ideal process gas filter is individually tailored to your requirements and process environment. Wire mesh laminate offers the necessary flexibility in shaping and allows a variety of processing options to create customised filter cartridges that achieve optimal results.

Details and standard dimensions:

-

Filter cartridges for process gas filtration File Size: 507 KB

-

Filter layers - Checklist File Size: 536 KB

![[Translate to English:] Porostar Muster Oberseite](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/1/4/csm_Porostar-Muster-Oberseite_1366x768_56d7a5d803.png)

![[Translate to English:] Porostar Muster Oberseite](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/1/4/csm_Porostar-Muster-Oberseite_1366x768_5be5451435.png)

![[Translate to English:] Porostar Muster Oberseite](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/1/4/csm_Porostar-Muster-Oberseite_1366x768_12221472ac.png)

![[Translate to English:] Querschnitt Porostar Light](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/8/5/csm_Querschnitt-Porostar-Light_1366x768_ccdbd1910b.jpg)

![[Translate to English:] Querschnitt Porostar Light](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/8/5/csm_Querschnitt-Porostar-Light_1366x768_34a2e3d70d.jpg)

![[Translate to English:] Querschnitt Porostar Light](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/8/5/csm_Querschnitt-Porostar-Light_1366x768_417fe9693d.jpg)

![[Translate to English:] Querschnitt Porostar Hiflo](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/c/f/csm_Querschnitt-Porostar-Hiflo_1366x768_ff34fd6f94.jpg)

![[Translate to English:] Querschnitt Porostar Hiflo](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/c/f/csm_Querschnitt-Porostar-Hiflo_1366x768_3b46b3740e.jpg)

![[Translate to English:] Querschnitt Porostar Hiflo](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/c/f/csm_Querschnitt-Porostar-Hiflo_1366x768_ca0ccb54a1.jpg)

![[Translate to English:] Querschnitt Porostar Combi](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/8/2/csm_Querschnitt-Porostar-Combi_1366x768_2ce99d53d7.jpg)

![[Translate to English:] Querschnitt Porostar Combi](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/8/2/csm_Querschnitt-Porostar-Combi_1366x768_c3a76490cd.jpg)

![[Translate to English:] Querschnitt Porostar Combi](https://www.haverboecker.com/fileadmin/HaverBoecker/_processed_/8/2/csm_Querschnitt-Porostar-Combi_1366x768_0c7c4d9c2b.jpg)

![[Translate to English:]](/fileadmin/HaverBoecker/DieDrahtweber/01_graphic/Profilbilder/christan-fortstroer.png)